Solutions for Hydroelectric Power

What is the problem?

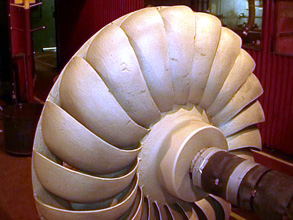

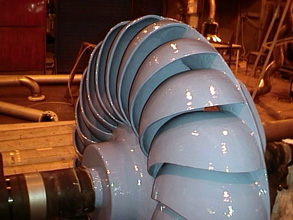

Fluid handling components such as the penstock, wicket gates, stay vanes and turbines can suffer from corrosion, erosion and cavitation damage, which may cause deterioration and lead to costly implications such as extended downtime. Traditional repairs can require lengthy downtime and typically require reapplication within the equipment lifetime.

Belzona Solution:

Belzona solutions for Hydropower eliminate corrosion by isolating the metal from the environment and reduce the effects of cavitation and erosion, utilizing erosion resistant composites and coatings. These solutions increase efficiency and asset life and at the same time lower maintenance costs. In-situ application and fast turnaround ensures that downtime can be minimized. Specialist tools are not required and the materials are cold-applied, eliminating the need for hazardous hot work.

Decades of experience servicing equipment in the Hydroelectric industry have positioned Belzona as a number one choice for combating erosion, corrosion and cavitation of fluid handling equipment. Applications are carried out by experienced and trained personnel to ensure the highest possible quality and value for our customers.

Erosion and Corrosion:

What is the problem?

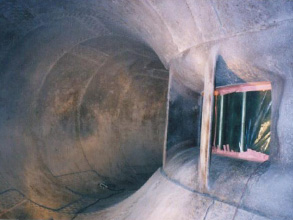

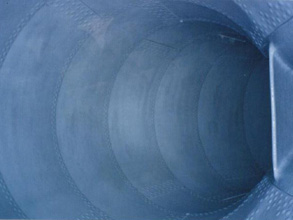

Solid particle entrainment leads to the erosion and subsequent degradation of the fluid handling equipment and the surrounding infrastructure such as penstock and spiral casing. Extended shutdown periods, loss of production and replacement can be costly and welding presents Health & Safety issues.

Belzona Solution:

Metal parts can be rebuilt to original profiles and exact dimensions using Belzona durable repair composites. Rebuilding can be achieved quickly, using cold applied materials that will not distort the substrate. Belzona 1111 (Super Metal) or Belzona 1311 (Ceramic R-Metal) are typically used for the rebuilding.

Deterioration of concrete surfaces caused by erosion can be quickly repaired using Belzona’s non-porous Magma products. Belzona 4111 (Magma-Quartz) or Belzona 4131 (Magma Screed) versatile multi-purpose repair composites can be easily used to resurface, rebuild and protect concrete and stonework providing excellent protection against abrasion, impact and chemical attack.

Belzona materials can withstand erosive forces for a considerable period of time. Therefore Belzona rebuilding can be considered a long-term solution, with many assets lasting 10 or more years longer than they originally would.

Where erosion is very severe, application of our composite materials avoids lengthy shutdowns and expensive replacement costs.

Belzona materials are quick, easy to apply, safe and cost-effective compared to traditional methods, such as welding or the replacement of the parts.

Decades of experience servicing equipment in the Hydroelectric industry have positioned Belzona as a number one choice for combating erosion, corrosion and cavitation of the fluid handling equipment. Applications are carried out by experienced and trained personnel to ensure the highest possible quality and value for our customers.

Cavitation:

What is the problem?

Cavitation is one of the problems affecting fluid handling equipment, such as turbine runners and wicket gates and can lead to increased running costs and subsequent equipment degradation.

Belzona Solution

Belzona offers a long-term solution to prevent cavitation damage, utilizing advanced polyurethane technology. It creates a durable, yet flexible, barrier between the fluid and metal which resists the impact of imploding cavitation bubbles, thus protecting fluid handling equipment.

Belzona 2141 (ACR-Fluid Elastomer) is a polyurethane coating which has a 10 year track record of resisting cavitation. Combined with a hydrophobic epoxy coating Belzona 1341 (Supermetalglide) and repair composites if needed, long-term corrosion, erosion and cavitation resistance can be achieved.

Belzona’s solution to cavitation is applied with minimal service disruption and does not require specialist tools. In situ application, fast cure and quick turnaround ensure that down time can be minimized.

Belzona materials are quick and easy to apply, safe and cost effective compared to traditional methods, such as welding or the replacement of the parts.

Decades of servicing equipment in the Hydroelectric Industry have positioned Belzona as a number one choice for combating erosion, corrosion and cavitation of the fluid handling equipment. Applications are carried out by experienced and trained personnel to ensure the highest possible quality and value for our customers.

Solutions for other areas

Belzona offers a diverse range of materials, designed to simplify equipment and building maintenance.

From sealing leaks in electrical transformers to floor and wall repairs, Belzona has been a global first choice for Hydropower equipment and structures maintenance since 1952.

Some of the solutions include:

- Pipework internal and external corrosion and erosion protection, as well as sealing live leaks. Solutions cover a wide range of pressures, temperatures and situations, including pipes that have lost structural integrity. In many cases application can be carried out on live pipework.

- Transformer oil and SF6 leaks can be permanently sealed utilizing surface-tolerant composites and coatings. Damaged ceramic insulators can also be restored in-situ.

- Floor epoxy coatings, safety grip systems and non-slip coatings are designed to provide lasting protection and reduce hazards.

- Concrete repair composites cure within hours and stop problems from reoccurring.

- Breathable, self-cleaning and aesthetic wall claddings are used to waterproof walls.

- Roofing membranes have the ability to seal a vast variety of contours and roofing materials. Membranes are breathable yet waterproof and stay watertight for the long term.

- HVAC systems are repaired and protected utilizing epoxy coatings and repair composites.

Belzona materials are quick, easy to apply, safe and cost-effective compared to traditional methods, such as welding or the replacement of the parts.

Decades of servicing equipment in the Hydroelectric Industry have positioned Belzona as a number one choice for combating erosion, corrosion and cavitation of the fluid handling equipment. Applications are carried out by experienced and trained personnel to ensure the highest possible quality and value for our customers.