Corrosion Under Insulation (CUI)

What is the problem?

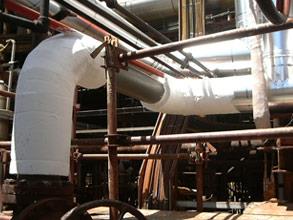

Pipework and vessels that operate at high temperatures are commonly insulated to prevent heat and energy loss as well as for health and safety reasons. The problem of Corrosion under Insulation (CUI) can occur on carbon steel, stainless steel and cast iron as a result of water ingress into and saturation of thermal insulation on pipework and vessels leading to rapid corrosion. Typical CUI problems include rapid surface corrosion and pitting leading to thin-wall defects and eventual failure.

Some of the causes for the presence of moisture may be:

- Water trapped in the insulation during construction, for example storage in places where moisture exists, application carried out during poor weather

- Joints in traditional claddings can form an inherent design weakness point

- Mechanical damage of traditional cladding

- Formation of condensation from elements such as cyclic temperature fluctuations

- Leaks in trace heating systems

- Poor fabrication standard of the protective cladding

Pitting corrosion, loss of structural integrity and ultimately loss of containment can occur and as the asset is insulated, such problems are not immediately visible and can remain undetected for some time leading to costly downtime.

What makes us different?

Belzona epoxy coatings and repair composites for the repair and protection of pipes and vessels against CUI have been proven to outperform conventional repair methods, providing the following key benefits:

Cost-effectiveness

- Heat-activated cure

Belzona's single-component products can be applied whilst equipment is online. They activate on application to hot surfaces ensuring minimal or no equipment downtime. - High adhesion and bond with minimal surface preparation requirements

Belzona materials adhere to metal substrates as a result of the high temperatures present. They do not require intensive blast cleaning or profiling, which results in fast application.

Ease of use and safety

- Reduced health and safety risks as our materials are 100% solids

Belzona heat-activated materials can be applied directly onto hot pipework and do not require preheating, avoiding the associated safety hazards.

Durability

- Chemical and heat resistance

Belzona materials provide protection from a wide range of chemicals at temperatures up to 150°C (302°F). - Excellent corrosion protection

Belzona CUI coatings and repair composites ensure long-term protection from the effects of corrosion.

Coating:

What is the problem?

Insulated pipework and vessels can deteriorate beneath the insulation due to water ingress into thermal insulation leading to rapid corrosion. Traditional repair methods require assets to be coated offline during a shutdown period, resulting in costly downtime and loss of production.

On stainless steel, CUI can cause surface pitting and chloride induced stress corrosion cracking. Failure can occur over a wide range of temperatures, the most critical range for CUI is between 30°C (86°F) and 120°C (248°F)., and risks can be increased during periods of shutdown.

The Belzona solution

Heat-activated and surface-tolerant products such as Belzona 5841 and Belzona 5851 (HA-Barrier) and can be applied directly onto hot surfaces with minimal preparation (SSPC-SP6, NACE#3) to stop and prevent corrosion, without the need for shutdown.

Depending on the temperature of the pipe or vessel, different Belzona products can be specified for online applications. In some cases, where there are temperature variations/gradients on the asset, more than one Belzona material can be used as part of a system, covering applications to assets with surface temperatures ranging from ambient up to 150°C (302°F).

Preventative protection of stainless steel assets will ensure no stress corrosion cracking will occur. Solutions to these problems can be challenging due to the fact that the work has to be done online, on hot surfaces, in hazardous areas and with restricted access. Belzona solutions for CUI not only stop corrosion but prevent it occurring in the future. They can be applied online and do not compromise safety requiring no hot work to prepare the substrate.

Rebuilding:

What is the problem?

On carbon steel and cast iron, corrosion can manifest itself as either generalized or localised. General surface corrosion can be resolved by applying a heat-activated protective coating. However, if the inspected equipment has suffered from severe corrosion and pitting or thin-walls are evident, a Belzona high temperature epoxy composite repair and rebuilding material can be used to rebuild the surface.

The Belzona solution

Where pitting is evident on equipment, Belzona 1251 (HA-Metal) can be used at temperatures ranging from 70°C (158°F) to 150°C (302°F) to rebuild the substrate to its original profile. This simple solution requires minimal surface preparation and can be completed without taking the equipment off line.

Where severe corrosion results in thin-walls below the corrosion allowance, thickness can be added to the outside of the pipework. Belzona 1251 (HA-Metal) can be applied directly onto the hot surface to bond plates, providing high adhesion and a quick repair. The corroded pipe walls can be repaired online with no outage required, providing a very cost-effective solution.

Insulation and Protection:

What is the problem?

As CUI is often unforeseen and can cause potentially catastrophic equipment failure, it is essential that pipework and vessels are inspected regularly. Thermal insulation materials need to allow easy access for inspection purposes as well as for quick reinstatement.

Traditional metal cladding materials have inherent weaknesses at joints, allowing water to penetrate through. Furthermore, traditional cladding systems can be easily damaged by external forces such as weight being applied by foot traffic. As a result, this causes further gaps between the joints increasing the risk of water penetration.

The Belzona solution

Belzona 3211 (Lagseal) is a water based microporous coating for the sealing and long-term protection of all types of thermal insulation. The material's microporous properties means it is ideal for applying to insulation as it allows moisture from underneath and inside the insulation to escape but at the same time, prevents any water penetrating the insulation.

As it is a single-component system, Belzona 3211 (Lagseal) is easy and safe to apply by brush and offers seamless application, even on complex contours. Repair and inspection can be carried out by simply cutting out a section which can be easily resealed by re-applying a reinforced coat of Belzona 3211 (Lagseal).